Product Description:

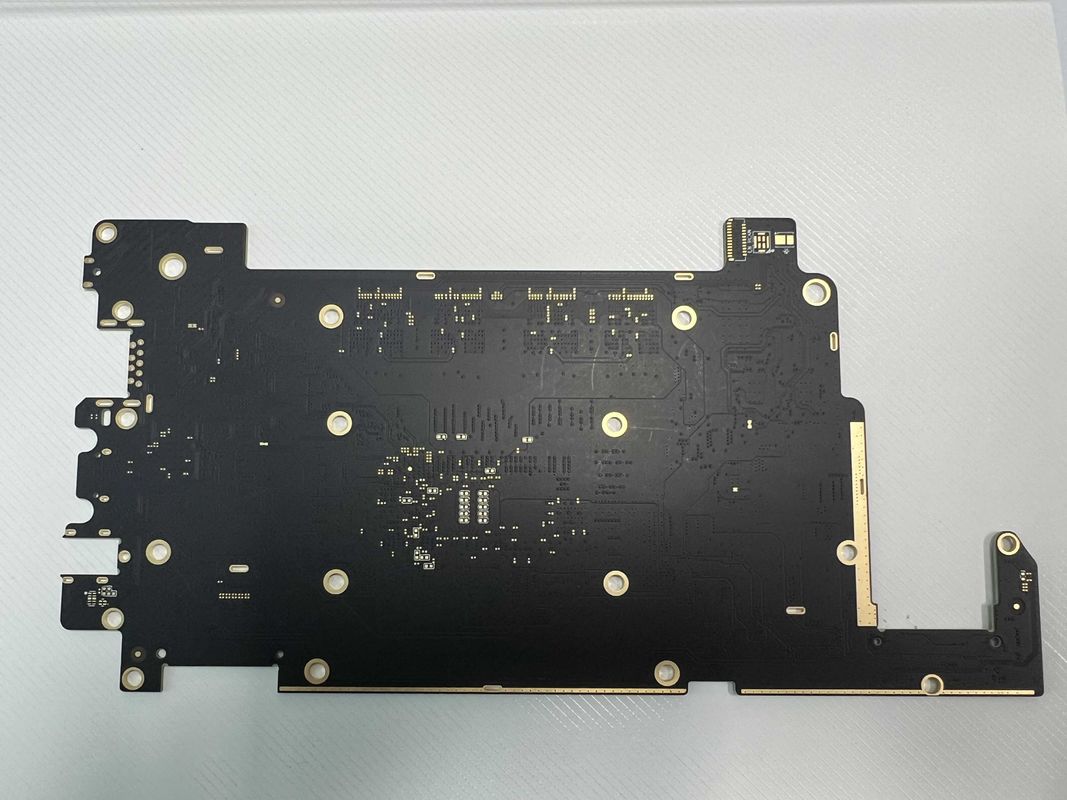

The HDI Printed Circuit Boards, also known as HDI PCB Boards, are advanced circuit boards that offer high-density interconnections using microvias and high-density interconnect technology. These boards are designed to provide exceptional performance and reliability for a wide range of electronic applications.

One of the key features of the HDI PCB Board is the Immersion Silver finish, which offers excellent solderability and oxidation resistance. This finish ensures reliable and consistent performance in various operating conditions, making it ideal for demanding applications.

The Finished Copper Thickness of the HDI PCB Board is 1oz, providing a good balance between electrical conductivity and thermal management. This thickness allows for efficient signal transmission and heat dissipation, contributing to the overall performance of the circuit board.

With Mini Holes as small as 0.1mm, the HDI PCB Board allows for high-density routing and compact designs. These tiny holes enable the connection of multiple layers within the board, increasing the routing density and reducing the overall size of the circuit board.

The Min. Solder Mask Bridge of 0.075mm ensures precise and reliable solder mask application, preventing short circuits and ensuring the integrity of the circuit traces. This narrow bridge helps to maintain signal integrity and reduce the risk of solder mask defects.

For Surface Finish options, the HDI PCB Board offers a variety of choices including HASL, ENIG, OSP, Immersion Silver, Immersion Tin, and more. These surface finishes provide different benefits such as corrosion resistance, solderability, and flatness, catering to the specific requirements of the application.

In conclusion, the HDI Printed Circuit Boards are the ideal choice for high-performance electronic devices that demand compact designs, high routing density, and reliable operation. With features such as Immersion Silver finish, 1oz Finished Copper Thickness, 0.1mm Mini Holes, and a range of Surface Finish options, these boards offer exceptional quality and performance for a wide range of applications.

Features:

-

Product Name: HDI PCB Board

-

Thickness: 1.6mm, ±10%

-

Pcb Assembly Process: SMT THT DIP SMT PCB Assembly

-

Finished Copper Thickness: 1oz

-

Key Words: High Density Interconnector

-

Vias Aspect Ratio: 16:1

Technical Parameters:

|

Surface Mount Technology

|

Available

|

|

Copper Thickness

|

0.5oz-6oz

|

|

Silkscreen

|

White, Black, Yellow, Etc.

|

|

Feature

|

Immersion Silver

|

|

Finished Copper Thickness

|

1oz

|

|

Surface Finish

|

HASL, ENIG, OSP, Immersion Silver, Immersion Tin, Etc.

|

|

Vias Aspect Ratio

|

16:1

|

|

Key Words

|

High Density Interconnector

|

|

Thickness

|

1.6mm, ±10%

|

|

Glass Epoxy

|

RO4350B Tg280℃, Er<3.48, Rogers Corp.

|

Applications:

When it comes to the product application occasions and scenarios for the HDI PCB Board, its versatile features and attributes make it an ideal choice for a wide range of industries and applications.

The HDI PCB Board is specifically designed to excel in high-speed applications where precision and reliability are crucial. With its ability to support the PCB assembly process through Surface Mount Technology (SMT), Through-Hole Technology (THT), and Dual In-line Package (DIP), this board is well-suited for various electronic devices and equipment requiring efficient assembly processes.

One of the standout features of the HDI PCB Board is its VIP process capability, ensuring enhanced performance and durability. The Vias Aspect Ratio of 16:1 further enhances its functionality, making it suitable for demanding applications such as High Definition Serial Digital Interface (HD SDI) converters.

Moreover, the availability of different silkscreen colors including white, black, yellow, etc., adds a customization element to the board, enabling manufacturers to incorporate branding elements or enhance visibility.

The high-speed capabilities of the HDI PCB Board make it an excellent choice for industries such as telecommunications, aerospace, automotive, and consumer electronics. Applications such as high-speed data transfer, signal processing, and high-definition video transmission can benefit significantly from the performance and reliability offered by this board.

Overall, the HDI PCB Board stands out as a top choice for applications requiring a combination of high-speed performance, precision assembly, and durability, making it a versatile solution for various industries and scenarios.

Customization:

Customize your HDI PCB Board with our Product Customization Services:

Finished Copper Thickness: 1oz

Pcb Assembly Process: SMT THT DIP SMT PCB Assembly

Silkscreen: White, Black, Yellow, Etc.

Mini Holes: 0.1mm

Copper Thickness: 0.5oz-6oz

Enhance your HDI PCB Board for your HD SDI Converter with our High Density Model Board and precision HDI PCB Manufacturing.

Support and Services:

Our Product Technical Support and Services for the HDI PCB Board include:

- Expert troubleshooting assistance for any technical issues

- Guidance on product installation and setup

- Comprehensive product documentation and user manuals

- Regular software updates and patches for improved performance

- Warranty support and repair services

- Training programs for users and technicians

Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!  Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!